Services

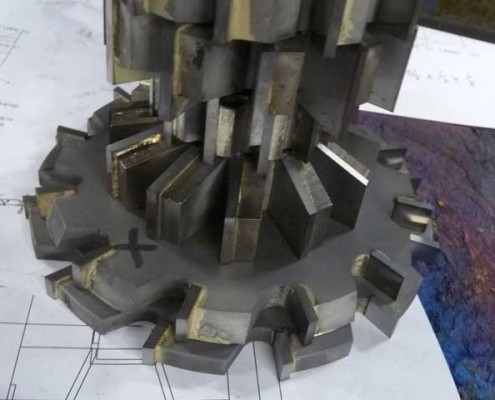

Complete saw sharpening and repair services:

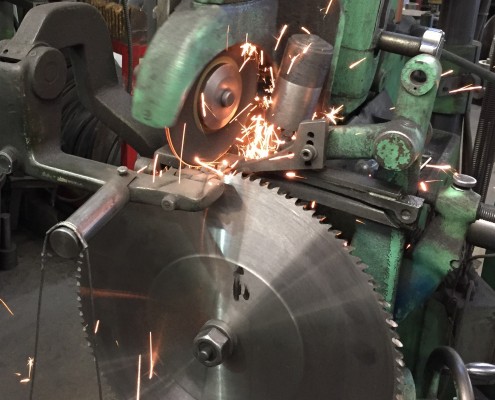

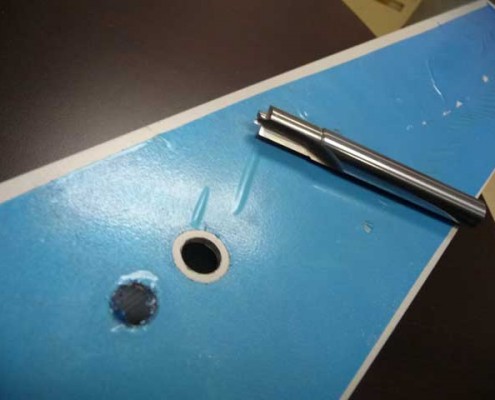

Circular saws, carbide, solid tooth and stellite, sharpened, repaired and re-tipped. Saws are initially cleaned using ultra-sonics, inspected for cracks and other damage, leveled and tensioned, then required grinding services are preformed on fully computerized European Grinders, using specially formulated Diamond and CBN Super Abrasive wheels.

We Specialize In:

- Precision rotary grinding capability up to 32” dia., with a tolerance of ±.0005”

- Knife grinding capability up to 125” long

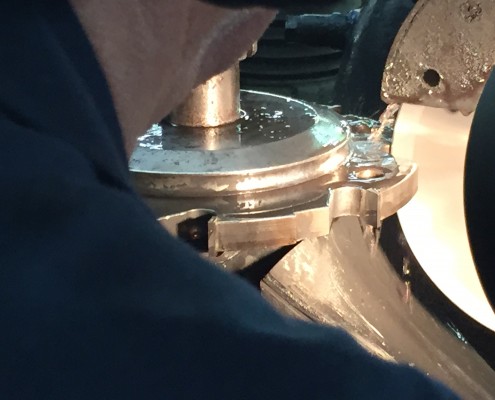

- Machine shop services: Metal Lathes, Milling machines

- Expert saw leveling and tensioning performed by skilled tradesmen. Saws are tensioned to match their revolution speed or to customers specifications.

- 7 tool and cutter grinders, Cincinnati and Haro (swiss)

- Profile and Surface Grinding

Our Service Advantage

-

- Being the only industrial saw manufacturer in the Lower Mainland, we have the equipment and inventory necessary to do all modifications, repairs and servicing to attain the maximum performance out of your cutting tools.

-

- Pressurized, high temperature saw cleaner is used to remove resins & wood build-up from your tools including ultra-sonic cleaning.

-

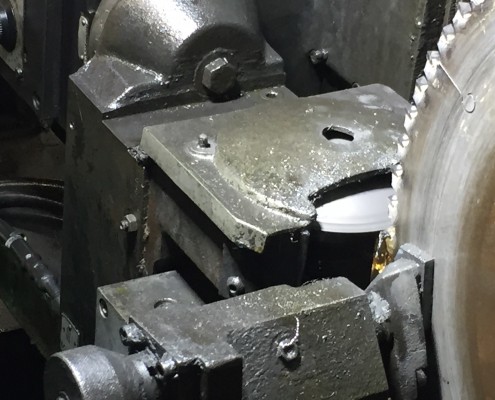

- We have seven liquid cooled Vollmer Automatic Saw Grinders and one oil-cooled 8 axis CNC fully robotic high-precision face and top grinder; including 2 CHP 21H with programmable micro processor computers. Vollmer is the world’s leader in saw sharpening technology. These machines offer the most precise grinding available.

-

- Vollmer Hollow Face Grinding. This German engineered grinding system offers the ultimate precision sharpening of Hollow Face saw blades.

-

- Diamond Wheels with micron fine grit and premium bonds, provide your tooling with the finest possible honed finishes.

-

- All panels, score and precision saw blades are checked for level and tension by our experienced Anvilman.

-

- Saws are individually assessed for how much carbide removal is necessary. Machines are then calibrated and your saw is ground, removing the minimal amount of carbide to ensure good performance and maximum blade life.

-

- Experienced servicemen assess the condition and value of your blade before proceeding with repairs. Making sure it is economically feasible.

-

- Saws are face and top ground every time, to ensure absolute precision and maximum blade life. Some saw shops sharpen faces only. This will dramatically reduce saw blade life and performance.

-

- At Carbide Tool Works (2008) Ltd we believe Customer Service is essential. We offer free pick-up and delivery to our local Customers.

CHD270 Vollmer Grinder with ND230 Robot Motor

JunZhi Auto Brazer 079